The use of Magnesium Anodes for Cathodic Protection is a proven and effective method to protect assets from corrosion:

Here are some examples of applications of Magnesium Anodes for Cathodic Protection:

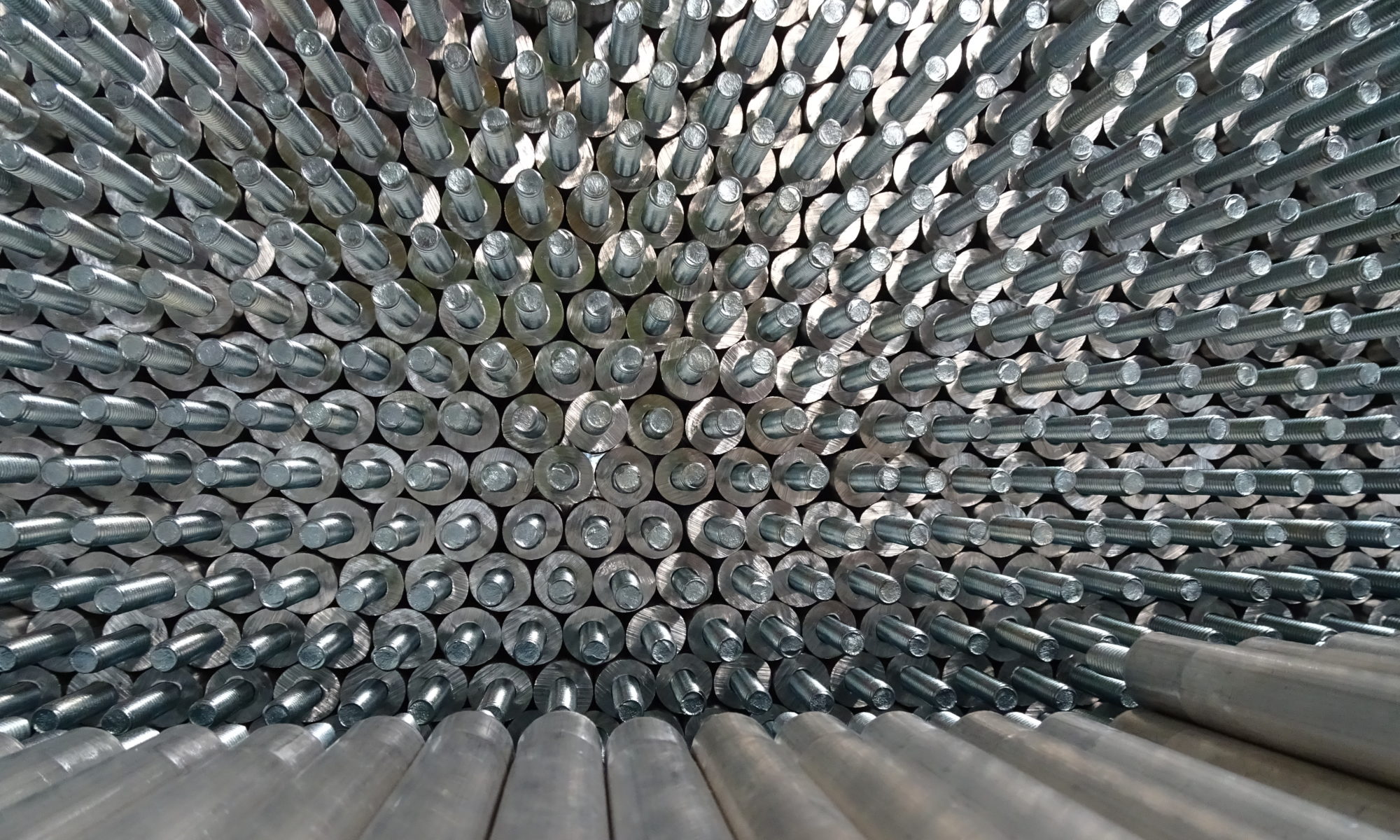

- Magnesium Soil Anodes – Hi-Potential and H-1 (Standard Potential)

- Magnesium Water Heater Anodes

- Magnesium Rod

- Magnesium Marine Anodes

Magnesium Anode Quality:

Strict quality measures are taken, including strategic choice of raw materials and continual quality control throughout the entire manufacturing process, resulting in the best performance of any magnesium anodes on the market

ASTM G97 Testing – Quality Assurance and Quality Control

Quality of High Potential Magnesium Anodes cannot be insured by Chemical Analysis alone. Performance Testing for anode closed circuit potential, open circuit potential, and anode mass loss to determine anode current capacity and efficiency is performed in a proper laboratory environment. Select control material is used per test batch

The only true and tested method of Quality Assurance of High Potential Magnesium Anodes is by testing as per ASTM G97

Galvotec’ Laboratory is one of very few laboratories in the world that is accredited to ISO Standard 17025:2017 to perform Testing in accordance to ASTM G97 also known as G97 testing

Composition:

The method of choice for the Chemical Analysis of Magnesium Anodes is Optical Emission Spectroscopy. The choice of certified, traceable primary standards for proper calibration is critical when utilizing this technique.

Magnesium Anode Testing and Quality Control– Galvotec operates an A2LA (ISO17025:2017) Accredited Laboratory for testing magnesium anodes and magnesium products. Optical Emission Spectrographic (OES) Analysis is utilized for assurance of chemical composition and ASTM G-97 is utilized for verification of electro-chemical properties.

Further technical details about anode testing are available at: http://www.galvotec.com/anode-testing.htm

High Potential Magnesium Soil Anodes conform to ASTM B843 Designation Grade M1C.

hi potential magnesium anode quality Galvotec High Potential Anode on the right side !

Galvanic Efficiency for Magnesium Hi-Potential Soil Anodes:

The current efficiency Galvotec Magnesium Hi-Potential (soil) Anodes is normally equal to or greater than 50% with current capacity of at least 500 amp-hr/lb or greater. Open Circuit potentials are normally equal to or more negative than -1.70 volts when referenced to copper/copper sulfate electrode.

The Standard Potential or AZ63 (H1) Series Anodes will typically produce open circuit potentials of -1.53 to -1.55 volts when referenced to copper/copper sulfate electrode. Typical anode current efficiency will be greater than 50% and current capacity will be greater than 500 amp-hr/lb or greater.

Applications:

Magnesium Brochures, Catalogs, and Flyers

- General Sacrificial Magnesium Anodes Catalog

- Extruded Magnesium Anodes Brochure – SuperRod (TM)

- Cast Magnesium Anodes Brochure – SuperMAG (TM)

- H1-Soil Anodes Flyer (for underground tanks)

Please Contact Us: For Magnesium Anodes and Cathodic Protection Products

Premium Magnesium Extrusions, Magnesium Die Castings, Magnesium Sacrificial Anodes, and Magnesium Products